News

Guía Silent Hill Geekzilla: Explora Cada Secreto del Juego

Published

6 months agoon

By

Anderson

Silent Hill es más que un videojuego; es una experiencia inolvidable que combina el terror psicológico con una narrativa profunda y atmosférica. En esta guía, “Guía Silent Hill Geekzilla”, te ayudaremos a descubrir todos los secretos del juego, desde consejos para principiantes hasta estrategias avanzadas que te permitirán superar cada desafío. Prepárate para adentrarte en un mundo oscuro lleno de monstruos, acertijos y emociones intensas.

¿Qué Es Silent Hill y Por Qué Es Tan Famoso?

Silent Hill es una legendaria franquicia de videojuegos de terror desarrollada por Konami. Desde su debut en 1999, ha cautivado a jugadores de todo el mundo gracias a su atmósfera inquietante, personajes memorables y narrativa compleja. Silent Hill no solo se enfoca en sustos repentinos; el verdadero terror proviene de su capacidad para jugar con la mente del jugador, explorando temas profundos como la culpa, el trauma y la redención.

La fama de Silent Hill también radica en su innovador uso de la música y los efectos de sonido. La banda sonora creada por Akira Yamaoka es icónica y ayuda a sumergir al jugador en un ambiente de constante tensión. Además, los gráficos, aunque básicos en sus primeras entregas, aprovecharon al máximo la tecnología de la época, usando la niebla como elemento clave para ocultar los límites del entorno y aumentar la sensación de misterio.

Cómo Empezar en Silent Hill: Consejos Para Principiantes

Adentrarte en Silent Hill puede ser intimidante, especialmente si es tu primera vez en un juego de terror psicológico. Aquí tienes algunos consejos esenciales para principiantes:

- Explora a fondo: Silent Hill está lleno de detalles ocultos. Dedica tiempo a investigar cada rincón, ya que podrías encontrar objetos útiles, pistas para resolver acertijos o incluso fragmentos de la historia.

- Escucha tu entorno: El sonido es clave en este juego. Los ruidos extraños o la ausencia total de sonido pueden ser indicios de peligros cercanos.

- No subestimes los recursos: La munición y los objetos de curación son limitados. Administra cuidadosamente lo que encuentres para no quedarte sin opciones en momentos críticos.

Recuerda que Silent Hill es un juego que recompensa la paciencia y la atención al detalle. Avanza con calma, observa tu entorno y no tengas miedo de retroceder si te sientes abrumado.

Personajes Claves en Silent Hill Que Debes Conocer

La narrativa de Silent Hill está impulsada por sus personajes, cada uno con una historia única y un trasfondo emocional profundo. Aquí hay algunos de los personajes más importantes que te encontrarás:

- Harry Mason (Silent Hill 1): El protagonista del primer juego, un padre desesperado en busca de su hija desaparecida, Cheryl. Harry es un personaje común y corriente, lo que lo hace más fácil de identificar para los jugadores.

- James Sunderland (Silent Hill 2): Protagonista de la segunda entrega, quien llega a Silent Hill tras recibir una carta de su difunta esposa. Su historia está cargada de misterio y simbolismo.

- Heather Mason (Silent Hill 3): La hija de Harry Mason, que se enfrenta a su propio viaje lleno de revelaciones impactantes. Heather es una de las protagonistas más queridas por los fans.

- Pyramid Head: Un icónico antagonista de la serie. Representa los demonios internos de los personajes y es uno de los monstruos más aterradores y simbólicos del juego.

¿Cómo Jugar Silent Hill Como Un Experto?

Domina Los Controles Básicos

El sistema de control de Silent Hill puede ser algo anticuado para los jugadores modernos, pero con práctica, dominarás las mecánicas rápidamente. Familiarízate con los botones para correr, apuntar y atacar. Además, ten en cuenta que la cámara fija puede ser un desafío, así que ajusta tu enfoque al entorno y a los enemigos.

Usa El Mapa De Forma Inteligente

El mapa es una herramienta esencial en Silent Hill. Te ayudará a encontrar puertas cerradas, rutas alternativas y lugares clave. Revísalo con frecuencia y marca las áreas que has explorado. La organización es clave para no perderte en la niebla.

Evita A Los Monstruos

En Silent Hill, la confrontación directa con los monstruos no siempre es la mejor opción. A menudo, es más inteligente evitarlos. Aquí tienes algunos consejos:

- Mantén la calma: Si un monstruo se acerca, no entres en pánico. Busca rutas de escape y aléjate con rapidez.

- Escucha la radio: El sonido de estática en tu radio indica que un enemigo está cerca. Usa esta información para planificar tus movimientos.

- Usa las sombras: Algunos monstruos tienen patrones de movimiento predecibles. Observa cómo se mueven y aprovecha para escabullirte sin ser detectado.

Trucos Y Secretos Para Ganar En Silent Hill

Silent Hill está lleno de secretos y trucos que pueden facilitarte el juego:

- Desbloquea finales alternativos: La franquicia es conocida por sus múltiples finales. Tus acciones, como cómo tratas a ciertos personajes o cuántos objetos curativos usas, pueden influir en el desenlace de la historia.

- Encuentra armas especiales: Algunos juegos de Silent Hill tienen armas ocultas, como la motosierra o el rifle de francotirador. Estas armas pueden marcar la diferencia en los combates más difíciles.

- Revisa las paredes y los muebles: Muchas pistas importantes están escondidas en los lugares más inesperados. No te limites a buscar en el suelo o los cofres; explora cada detalle.

Guía Para Principiantes En Silent Hill

Para los nuevos jugadores, esta guía les permitirá empezar con buen pie:

Los Mejores Ajustes De Dificultad

Silent Hill permite ajustar la dificultad tanto en los combates como en los acertijos. Si eres principiante, elige una dificultad baja para centrarte en la historia y el ambiente sin preocuparte demasiado por los enemigos.

Los Objetos Más Útiles Del Juego

Algunos objetos, como el kit de primeros auxilios y las bebidas energéticas, son esenciales para sobrevivir. Además, busca armas secundarias como el tubo de acero o la pistola para estar siempre preparado.

Cómo Resolver Los Puzzles Más Difíciles

Los acertijos de Silent Hill pueden ser desafiantes, pero la clave está en observar las pistas cuidadosamente. Si te atascas, revisa tu inventario y los documentos que hayas recogido, ya que suelen contener pistas valiosas.

Los Mejores Momentos De Silent Hill

Silent Hill está lleno de momentos memorables que han quedado grabados en la mente de los jugadores. Desde el aterrador encuentro con Pyramid Head en Silent Hill 2 hasta la revelación final de la historia de James Sunderland, cada juego ofrece escenas impactantes que combinan terror, emoción y narrativa. Estos momentos no solo son inolvidables, sino que también elevan la franquicia a un nivel artístico único.

The Bottom Line

Silent Hill es mucho más que un simple videojuego; es una experiencia que combina el terror psicológico con una narrativa profunda y personajes memorables. Con esta guía, “Guía Silent Hill Geekzilla”, esperamos haberte preparado para explorar cada rincón de este oscuro y fascinante mundo. Recuerda explorar con calma, planificar tus movimientos y, sobre todo, disfrutar de cada momento de este clásico inolvidable. ¿Estás listo para enfrentar la niebla y descubrir los secretos de Silent Hill? ¡Adelante, valiente explorador!

You may like

News

What Is a Food Grade Trailer? (Easy Guide for Beginners in the USA)

Published

9 hours agoon

July 9, 2025By

Anderson

If you’ve ever wondered how fresh fruits, milk, juices, or even packaged snacks safely get to your grocery store shelves, the answer often involves a food grade trailer. In the United States, these specialized trailers play a critical role in transporting food items without contamination. In this beginner-friendly guide, we’ll explain what food grade trailers are, why they’re important, and everything else you need to know about them. Whether you’re curious about logistics or planning to get into the food transport business, this guide will make it easy to understand.

What Is a Food Grade Trailer?

A food grade trailer is a type of truck trailer specifically designed and maintained to transport food products safely. Unlike standard freight trailers, food grade trailers meet strict cleanliness and safety standards to ensure that whatever is carried inside stays uncontaminated and fresh. These trailers are built with materials and designs that prevent any form of contamination, including odors, bacteria, and residue from previous loads.

Food grade trailers can be tankers that carry liquids like milk or juices, dry vans for packaged foods, or refrigerated trailers for perishables. To be considered “food grade,” a trailer must pass inspections and comply with regulations set by the U.S. Food and Drug Administration (FDA) and the Food Safety Modernization Act (FSMA).

Why Do We Need Food Grade Trailers?

Transporting food is not as simple as loading boxes onto any truck. Food products can spoil, absorb odors, or even become dangerous if they’re not handled properly. This is where food grade trailers come in. They ensure that food stays clean, fresh, and safe from the time it leaves the producer until it reaches stores or restaurants.

For example, a tanker that once carried fuel cannot be used for milk unless it has been properly cleaned and certified food grade. Without these trailers, cross-contamination could lead to foodborne illnesses and huge public health risks. In short, food grade trailers protect consumers, maintain food quality, and help companies comply with strict food safety laws in the U.S.

Types of Food Grade Trailers

Food grade trailers come in different types, each designed for specific kinds of food products. Choosing the right one depends on what’s being transported, how far it needs to go, and whether temperature control is required. Let’s break down the most common types:

Tanker Trailers

Food grade tanker trailers are stainless steel tanks on wheels. They’re primarily used for transporting bulk liquids like milk, cooking oils, juices, and even liquid sweeteners like corn syrup. These tankers must be insulated to keep the contents at the right temperature and must be thoroughly cleaned between loads to avoid cross-contamination.

The interior of these tankers is smooth and polished to prevent residue from sticking, making cleaning and sanitizing easier. In the U.S., they must meet the 3-A Sanitary Standards for dairy and other liquid foods.

Dry Van Trailers

Dry van trailers are the most common food grade trailers for packaged and non-perishable food items. They are enclosed trailers that protect cargo from outside elements like rain, dust, or pests. These trailers are ideal for products like canned goods, cereals, flour, sugar, and packaged snacks.

To qualify as food grade, a dry van must be free from odors, moisture, and any signs of pest infestation. It must also have smooth, cleanable walls and floors.

Refrigerated Trailers (Reefers)

Refrigerated trailers, or reefers, are essential for transporting perishable foods such as meat, seafood, dairy, and frozen products. These trailers have built-in cooling systems that maintain a specific temperature throughout the journey.

In the U.S., strict rules govern how reefers are maintained and cleaned. Temperature monitoring systems are often installed to ensure food safety during transit. Reefers help prevent spoilage and keep foods fresh from farm to table.

How Are Food Grade Trailers Cleaned?

Cleaning is a critical step for maintaining food grade standards. After each load, trailers must be sanitized to remove residues, odors, and potential contaminants. This process often involves high-pressure washing with hot water, food-safe detergents, and sometimes steam cleaning.

For tanker trailers, the cleaning process is known as a “washout” and is performed at certified wash stations. These stations provide a wash ticket as proof of sanitation, which shippers often require before loading new food cargo. Dry vans and reefers also undergo similar cleaning processes, focusing on floors, walls, and air systems.

Failure to properly clean food grade trailers can result in rejected loads, hefty fines, and even health hazards. That’s why carriers invest in regular cleaning and inspection schedules.

Rules for Food Grade Trailers in the USA

In the United States, the FDA regulates food transportation under the Sanitary Transportation of Human and Animal Food rule, part of the FSMA. This rule sets guidelines for:

- Cleaning and maintenance: Trailers must be regularly cleaned and kept in sanitary condition.

- Temperature control: Reefers must maintain specified temperatures, with records available for inspection.

- Loading and unloading practices: Preventing contamination during these processes is critical.

- Training: Drivers and handlers must be trained in sanitary transportation practices.

Carriers are also responsible for maintaining detailed records of cleaning, maintenance, and temperature monitoring. Non-compliance can lead to penalties or being barred from hauling food loads.

Common Foods Carried in Food Grade Trailers

Food grade trailers carry a wide variety of products across the U.S. Here are some of the most common categories:

Fresh Produce

Fruits and vegetables require clean, pest-free trailers and often temperature control to stay crisp and fresh. Reefers are commonly used for these loads.

Dairy and Beverages

Milk, cream, yogurt, juices, and soft drinks often travel in food grade tanker trailers or reefers. These products are highly sensitive to temperature changes and contamination.

Packaged Snacks

Chips, cookies, cereals, and other shelf-stable foods are typically transported in dry van trailers. Even though these are packaged, cleanliness of the trailer is still essential to prevent exposure to odors, moisture, or pests.

Words About Food Grade Trailers

Food grade trailers are more than just trucks on the highway; they are an integral part of the food supply chain. Without them, maintaining the safety and quality of food during transportation would be nearly impossible. Their design, cleaning processes, and regulatory oversight ensure that when you grab a snack or pour a glass of milk, it’s as fresh and safe as it was at the source.

The Bottom Line

For anyone involved in food logistics, understanding food grade trailers is crucial. These specialized trailers ensure the safe and sanitary transportation of food products across the U.S. From tanker trailers hauling bulk liquids to reefers keeping perishables cold, each type plays a unique role in feeding millions every day. As regulations tighten and consumer expectations rise, the importance of food grade trailers will only grow. Whether you’re a shipper, carrier, or simply curious, knowing how these trailers work gives you a deeper appreciation for the unseen systems that keep our food safe.

News

What Does Most Damage to Circuit Board? Simple Guide for Beginners

Published

9 hours agoon

July 9, 2025By

Anderson

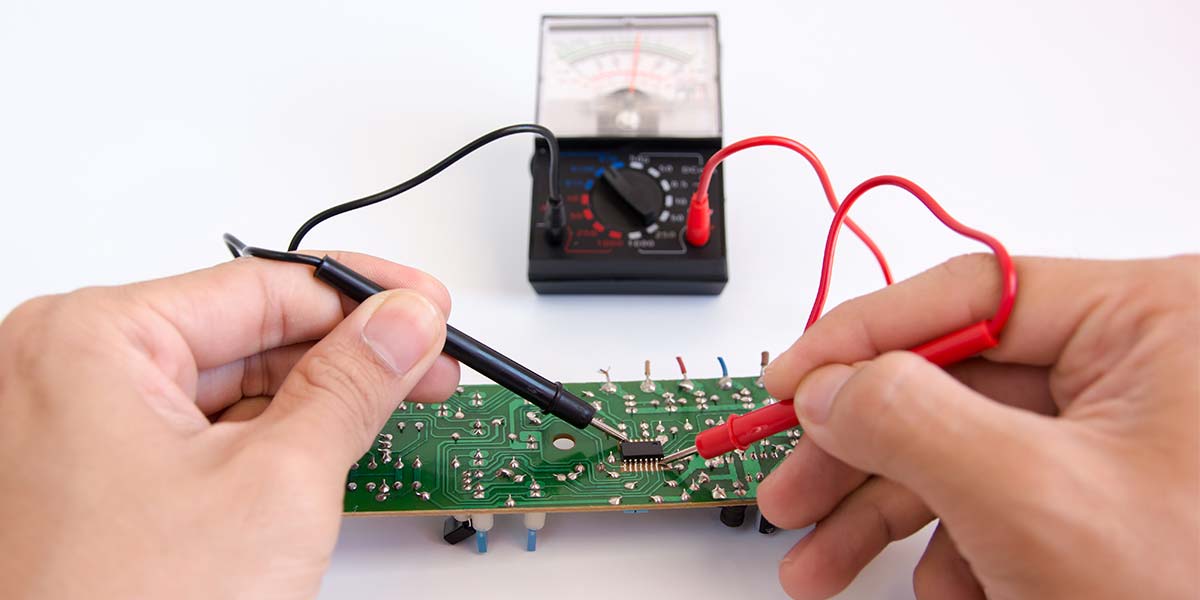

Circuit boards are the heart of almost every electronic device. From your smartphone to your refrigerator, these tiny green boards hold countless components working together. But they’re also very fragile. Understanding what damages a circuit board the most is key to keeping your devices running longer. In this guide, we’ll explain all the common threats to circuit boards and how you can protect them.

What Damages Circuit Boards the Most?

Circuit boards may look tough, but they’re surprisingly delicate. The most common things that damage them include heat, moisture, static electricity, dust, and even using cheap or low-quality parts. These threats can lead to cracks, corrosion, burnt components, and complete failure of the board.

When a circuit board fails, the device it powers can stop working completely. This is why engineers and technicians always focus on protecting boards during manufacturing and after installation. For the average person, knowing these dangers helps you avoid accidents that can ruin expensive electronics.

Can Heat Destroy a Circuit Board?

Yes, heat is one of the biggest enemies of circuit boards. Excessive heat causes the solder (the tiny metal connections on the board) to soften or melt. It can also damage microchips and make plastic parts brittle. Over time, this heat stress leads to broken connections and permanent damage.

Heat doesn’t only come from external sources like sunlight or a nearby heater. Inside devices, components like processors and power supplies generate heat too. If this heat isn’t managed with fans, heat sinks, or proper ventilation, it can destroy the board slowly.

How Hot is Too Hot for a Circuit Board?

Most circuit boards are designed to handle temperatures up to around 85°C (185°F) for standard consumer electronics. Some industrial boards can handle slightly higher temperatures. But anything above 100°C (212°F) is dangerous and can damage components quickly.

High heat can cause the board to warp or expand. It can also cause “thermal runaway” where heat causes more current to flow, which creates even more heat in a vicious cycle. Even short exposure to extreme temperatures (like leaving your laptop in a car on a hot day) can be enough to harm the board.

Why Overheating Happens So Often

Overheating isn’t rare. It often happens because devices are used in poorly ventilated spaces, clogged with dust, or placed on soft surfaces that block airflow. Gaming consoles, laptops, and routers are all vulnerable if their cooling systems fail. Even a broken fan can lead to overheating in a desktop PC.

Simple Tips to Stop Heat Damage

To avoid heat damage:

- Keep vents clear and never block airflow.

- Regularly clean fans and vents to prevent dust buildup.

- Use devices in air-conditioned spaces if possible.

- Avoid charging or using electronics on soft surfaces like beds.

- Replace thermal paste and faulty fans in aging devices.

Does Water Hurt Circuit Boards?

Absolutely. Water and electronics don’t mix. Even a small amount of moisture can cause short circuits, corrosion, and rust on a circuit board. This is why water-damaged phones and laptops often stop working.

Humidity is also a silent enemy. In damp environments, moisture in the air can settle on the board, leading to slow corrosion over months or years. If you live in a humid area, using a dehumidifier or keeping devices in dry spaces is essential.

How Dust and Dirt Damage Boards

Dust might not seem dangerous, but it’s a major threat to circuit boards. As dust accumulates, it traps heat and blocks ventilation. This causes the device to overheat faster. Dust particles can also absorb moisture from the air, creating a conductive layer that leads to shorts or corrosion.

In environments like workshops or homes with pets, circuit boards are more exposed to dirt, hair, and debris. Over time, this grime can create physical barriers between components and cause them to fail.

Why Clean Boards Last Longer

A clean circuit board runs cooler and stays functional longer. Removing dust and dirt reduces the chance of overheating, corrosion, and even electrical shorts. Regular cleaning is a simple habit that can save you from costly repairs or replacements.

Best Way to Clean a Circuit Board Safely

Cleaning circuit boards isn’t complicated but requires care. Here’s how:

- Turn off and unplug the device. Never clean a live board.

- Use compressed air to blow away loose dust and debris.

- For stubborn grime, use isopropyl alcohol (99%) and a soft brush. Avoid water or household cleaners.

- Be gentle. Pressing too hard can damage delicate components.

- Let it dry completely before turning the device back on.

Never use a vacuum cleaner directly on a circuit board because static electricity from vacuums can harm sensitive components.

Can Static Electricity Kill Circuit Boards?

Yes. Static electricity is invisible but deadly to circuit boards. Even a small static discharge from your finger can fry sensitive microchips. This is why technicians use anti-static wrist straps and mats when working on electronics.

What About Power Surges?

Power surges are sudden spikes in electricity. They often happen during storms or due to unstable power grids. A strong surge can burn components and melt traces on a circuit board instantly. Using surge protectors or uninterruptible power supplies (UPS) helps shield devices from these threats.

Why Quality Matters in Circuit Design

High-quality boards use better materials and designs to resist damage from heat, static, and power fluctuations. Cheap boards often lack proper protective coatings or robust components, making them fail faster under stress.

Are Cheap Parts Bad for Circuit Boards?

Yes, using cheap or counterfeit parts is risky. Low-quality components may not meet safety or performance standards. They can overheat, fail prematurely, or even damage other parts of the circuit. Investing in quality components upfront saves money and headaches in the long run.

The Bottom Line

Circuit boards are the backbone of modern electronics, but they’re vulnerable to heat, moisture, dust, static electricity, and cheap components. By understanding what causes the most damage to circuit boards and taking simple precautions, you can extend the life of your devices and avoid costly repairs. Keep them clean, cool, and protected from environmental threats. Treat your gadgets with care, and they’ll serve you well for years to come.

News

Where to Buy Ilco Key Remotes as General Public (Easy Guide)

Published

9 hours agoon

July 9, 2025By

Anderson

If you’re searching for where to buy Ilco key remotes as general public in the United States, you’re not alone. Many car owners, locksmiths, and even DIY enthusiasts often wonder how and where they can legally and easily purchase these remotes without needing a dealer license. This easy guide breaks down everything for you step by step, so even a 10-year-old can understand where to get them, what to check before buying, and how to get the best deals online and offline.

Best Places to Buy Ilco Key Remotes in the USA

Ilco key remotes are widely used across the United States for car keys, garage doors, and security systems. But finding the right place to buy them as a member of the general public can sometimes feel confusing. The good news? You don’t need to be a professional locksmith or an authorized dealer to get your hands on Ilco remotes. Whether you’re replacing a lost remote or want a backup, there are plenty of options out there.

In the US, you can buy Ilco remotes from a mix of online retailers, local locksmith shops, and even hardware stores. Each comes with its own pros and cons. Online stores often offer better pricing and larger inventories, while local shops can provide personalized service and instant help with programming. Knowing where to look can save you money and time.

Can the Public Buy Ilco Key Remotes?

This is a common question because Ilco is a trusted name in security products, and some people assume their products are restricted. The answer is simple: yes, the public can buy Ilco key remotes. Ilco does sell directly to locksmiths and authorized dealers, but they also allow their products to be sold on platforms that are accessible to everyone.

However, there’s a catch: while you can purchase the remote, programming it to work with your vehicle or lock system might still require professional tools or help from a locksmith. But don’t worry—many sellers online and offline offer pre-programmed remotes or provide programming guides.

Online Stores That Sell Ilco Remotes

Buying Ilco key remotes online is one of the easiest and most popular options today. You get access to a wide variety of models, competitive pricing, and customer reviews to guide your decision.

Amazon – A Simple Option

Amazon is one of the most convenient places to buy Ilco remotes. You can find a huge selection of both original and compatible remotes. Many listings even include programming instructions or links to video tutorials. Plus, Amazon’s fast shipping options mean you can get your remote within a day or two in most parts of the United States.

You can also check customer reviews to ensure the seller is reputable and the remote is of good quality. Look for listings marked “fulfilled by Amazon” for quicker returns if something doesn’t work as expected.

eBay – Good for Deals

eBay is another great place for people looking for Ilco key remotes, especially if you’re on a budget. You can often find new or slightly used remotes at discounted prices. Auctions may even allow you to score a deal far below retail.

But, be cautious: verify the seller’s rating and make sure the remote is compatible with your specific car model or security system. Some sellers on eBay even offer bulk purchases, which can be handy for small businesses or families needing multiple remotes.

Official Ilco Dealers Online

For those who prefer buying directly from official sources, there are many authorized Ilco dealers online. Websites like Ilco’s official site and affiliated distributor pages sell genuine Ilco remotes. While prices might be a little higher than on Amazon or eBay, you’re guaranteed to receive authentic products with full manufacturer support and warranties.

Local Shops Where You Can Buy Ilco Key Remotes

If you’re not comfortable buying online or need help with programming, your local options are worth exploring. Locksmith shops, hardware stores like Home Depot or Lowe’s, and even some auto parts stores stock Ilco key remotes.

Local locksmiths are particularly helpful because they can assist with cutting and programming the key. While they may charge a bit more than online sellers, the added convenience of walking out with a fully functional remote often makes it worth it.

Another advantage of shopping locally is the ability to ask questions face-to-face and get expert recommendations tailored to your needs.

Tips Before You Buy Ilco Key Remotes

Before buying an Ilco remote, there are a few things you should keep in mind to avoid wasting money or buying the wrong product:

- Check compatibility: Not every Ilco remote works with every vehicle or lock system. Verify your model and year before purchase.

- Buy from trusted sellers: Whether online or offline, stick to sellers with good reputations and positive customer reviews.

- Ask about programming: Some remotes can be programmed at home, while others may require a professional’s help.

- Compare prices: Prices can vary widely between sellers, so shop around to get the best deal.

- Look for warranties: Many reputable sellers offer warranties or return policies.

Are Ilco Remotes Cheaper Online or Offline?

This is a question many buyers have, and the answer depends on a few factors. In general, online prices tend to be lower because sellers have less overhead. But buying offline has its own advantages, like instant service and assistance.

Check Compatibility

Online listings often list all compatible models in the description. Make sure your car’s make, model, and year are supported. If in doubt, contact the seller directly before buying.

Compare Prices Online

Shopping online allows you to quickly compare prices between Amazon, eBay, and official Ilco dealers. Look for free shipping offers, coupons, or bulk discounts.

Look for Warranties

When buying online, always check if the seller offers a warranty or satisfaction guarantee. Some online marketplaces provide 30-day return policies, but official dealers often include a manufacturer’s warranty that covers defects.

Thoughts – Buying Ilco Remotes Made Easy

Buying Ilco key remotes as a member of the general public is not as difficult as it might seem. Thanks to a wide range of online and offline options, you can easily find and purchase the right remote for your needs. Just remember to double-check compatibility, read reviews, and choose a trusted seller.

The Bottom Line

If you’re in the United States wondering where to buy Ilco key remotes as general public, the answer is simple: you have plenty of options. From Amazon and eBay to local locksmiths and official Ilco dealers, you can shop where it’s most convenient for you. Take a little time to research, and you’ll have your new remote in hand quickly and at the best possible price.

What Is a Food Grade Trailer? (Easy Guide for Beginners in the USA)

What Does Most Damage to Circuit Board? Simple Guide for Beginners

Where to Buy Ilco Key Remotes as General Public (Easy Guide)

TuGuiaUSA.com, Empleos y Oportunidades en USA

Camille Monfort, Shadows of the Crimson Moon

Breaking News: Tea Leoni and Tim Daly Announce Split

Trending

-

Business7 months ago

Business7 months agoTuGuiaUSA.com, Empleos y Oportunidades en USA

-

Life Style7 months ago

Life Style7 months agoCamille Monfort, Shadows of the Crimson Moon

-

Life Style7 months ago

Life Style7 months agoBreaking News: Tea Leoni and Tim Daly Announce Split

-

Games7 months ago

Games7 months agoUnlocking Access to Unblocked Games World at School

-

Life Style7 months ago

Life Style7 months agoJulio Urias Wife: Inside His Life with Daisy

-

Life Style7 months ago

Life Style7 months agoIgAnony: The Anonymous Instagram Story Viewer

-

Education7 months ago

Education7 months agoTribute Printed Pics: A Special Way to Remember

-

Technology11 months ago

Technology11 months agoGeekzilla Radio – Your Ultimate Geek Culture Nexus